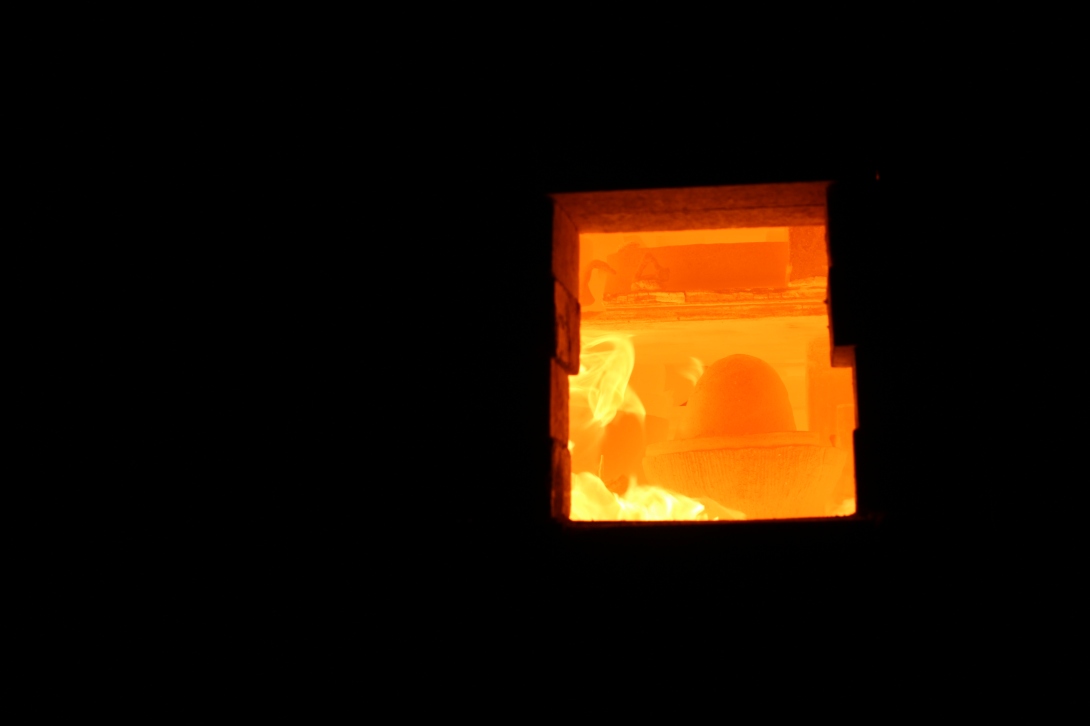

Lately we’ve been working on our woodfire kiln. It’s actually a small test kiln inspired by japanese anagama. We fired it for three times, the results were better after every next firing, but the kiln fell a part after the last try, so probably we’ll not be able to fire it again. Anyway our plan for the future is to build a bigger kiln made of bricks.

It’s a special expedition every time we go woodfiring. We go to Kozarisce, where we used to live and where we started with our ceramics. There is David’s grandmothers house in this rural area of Slovenia. Kozarisce is a small village with a big castle surrounded by wast woods. Wild animals live in the woods and also the brown bear. Better not go to far in the woods at night! Ha ha!

It’s a few days project every time we are firing. Preparations have to be made, put the kiln together, make some improvements with the fire place, prepare the pieces and loading. Usually it takes one day. Since we go there together with our daughter, David does most of the “fire work”.

Here are some results of firing, we reached 1230 °C and the total firing time was 24 hours in the first attempt and 28 hours in the last attempt.